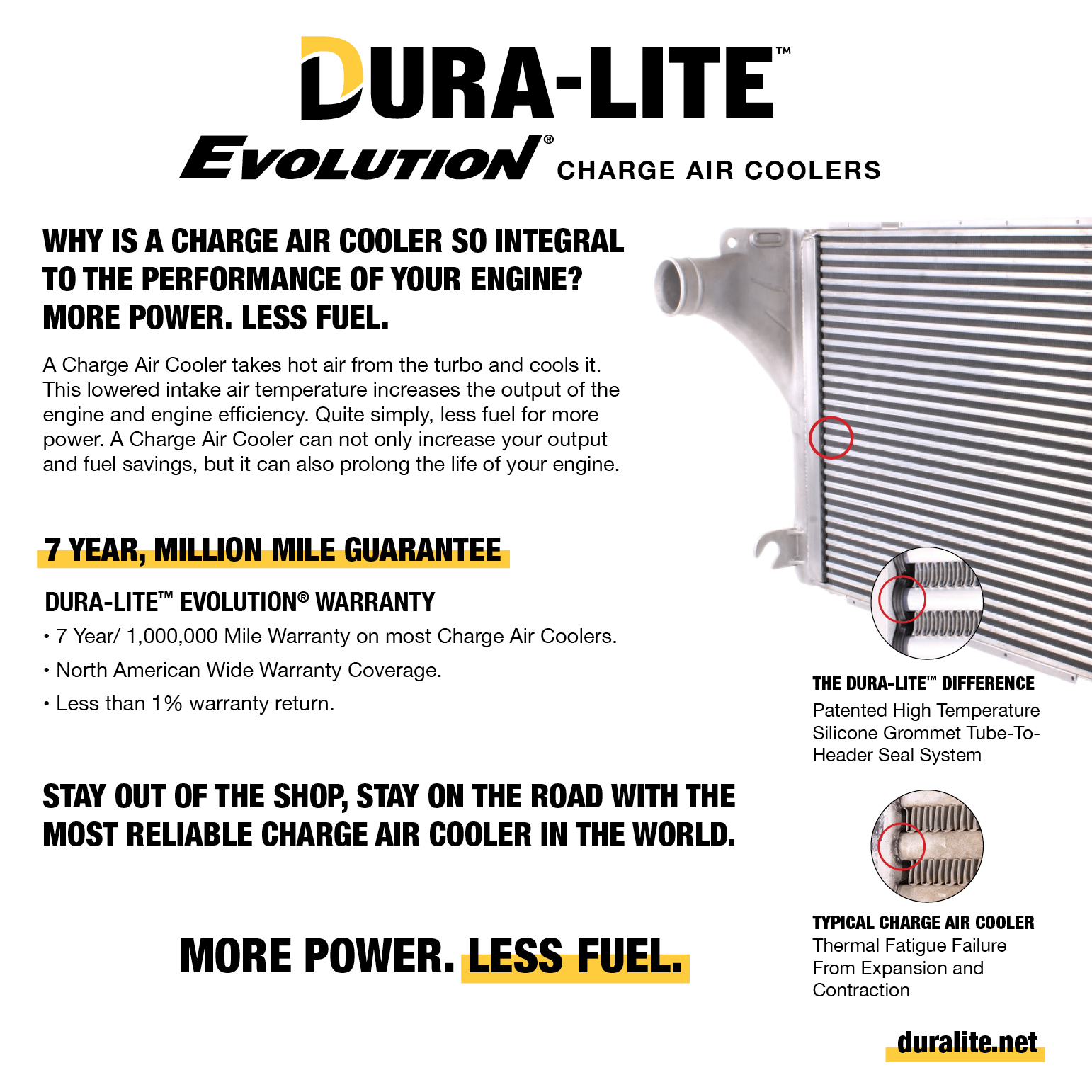

OEM and other aftermarket coolers often crack at the rigid tube to header joint. Dura-Lite has replaced this rigid joint with our Patented High Temperature Silicone Grommet Tube-To-Header Seal System.

This provides a long, leak free Charge Air Cooler life.

Engineered for performance, economy, and durability (longevity).

EPA certified (where required).

Dyno tested to assure the highest performance.

Each cooler is pressurized and tested under water to assure it is 100% leak free before leaving the factory.

Superior quality and the best warranty in the industry reduce downtime.

From day one, Dura-Lite™ has been committed to solving the Charge Air Cooler durability problems vehicle owner/ operators face. When Dura-Lite™ started on this project, we knew that we had to engineer a Charge Air Cooler that met the required OE engine performance specifications. We also knew we had to produce a Charge Air Cooler which would last - not for months or a couple of years, but for many years! This commitment to Quality and Excellence placed Dura-Lite™ in a unique position. While other Charge Air Cooler manufacturers were attempting to improve upon the typical Charge Air Cooler thermal fatigue failure (OE design), Dura-Lite™ took another approach.

Dura-Lite™ engineered a Charge Air Cooler incorporating our Patented Silicone Grommet Tube-to-Header Seal System in place of the traditional brazed/ welded tube to header joint. The silicone grommets allow for free thermal expansion while maintaining a leak free seal. This free thermal expansion eliminates the stress and premature failures associated with a restrained brazed/ welded tube to header joint. Strain tests, thermal cycle tests, dynamometer tests, durability tests at elevated temperatures, and field tests were conducted. Dura-Lite™ coolers produced outstanding results and confirmed that our engineers had, indeed, found the solution to eliminating premature Charge Air Cooler failure.

Last updated: Monday, 22 April 2024 04:42 PM